Inexpensive Opel Corsa Engine Options for Your Spending plan

Checking Out the Inner Operation of a Compact Vehicle's Engine System

As motorists, we frequently take for approved the elaborate processes that take place within the boundaries of our vehicle's engine system. In this exploration of a portable automobile's engine system, we will decipher the inner operations of this mechanical symphony, shedding light on the mysteries that drive us ahead on our everyday trips.

Burning Process Review

The combustion process in a small vehicle's engine system is an important system that efficiently transforms fuel into power to power the car. This process takes place within the combustion chamber of the engine, where gas and air mix, spark, and create controlled explosions. The burning procedure includes 4 primary stages: consumption, exhaust, power, and compression.

Throughout the intake phase, the piston moves downward, reeling in a mix of air and gas into the burning chamber. The following phase, compression, involves the piston moving upward, compressing the air-fuel blend to raise its strength. Ultimately, in the power phase, the spark plug sparks the compressed mix, leading to a rapid development of gases that forces the piston back down. This downward activity generates the power required to drive the vehicle. In the exhaust phase, the burnt gases are gotten rid of from the combustion chamber via the exhaust valve, preparing the chamber for the next cycle. This cyclic combustion process is essential to the operation of a compact automobile's engine system, making sure effective power conversion for propulsion.

Piston and Cyndrical Tube Interaction

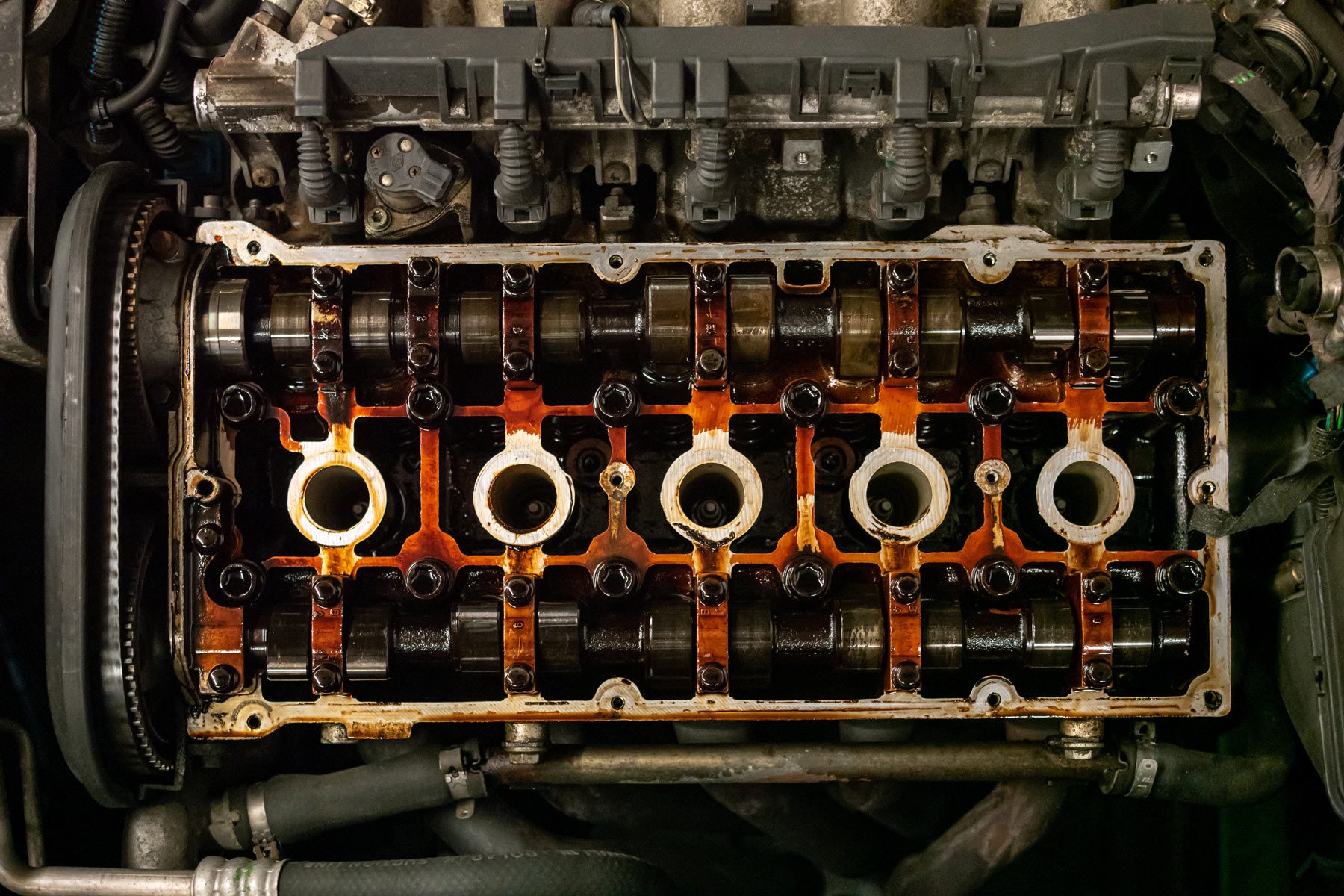

The piston's specific fit within the cyndrical tube is important for maintaining optimal compression and protecting against energy loss throughout combustion. Limited clearances in between the piston and cylinder walls guarantee efficient securing, allowing the piston to move smoothly without enabling gases to leak past. Appropriate lubrication is additionally important to decrease friction and use between these parts, boosting longevity and performance.

Additionally, the design and materials made use of in making the piston and cylinder impact engine effectiveness and resilience. Modern engines commonly use lightweight yet sturdy materials like aluminum alloys for pistons and cyndrical tube liners to decrease inertia and boost thermal performance. Overall, the unified interaction in between the piston and cylinder is essential to the engine's capability and overall efficiency.

Fuel Shot System Performance

Fuel shot systems in compact automobile engines play an important function in specifically supplying fuel to the burning chamber for reliable and regulated ignition. The fuel shot system works by injecting fuel into the burning chamber at the optimum moment during the engine's procedure (opel corsa engine). This accurate timing makes sure that the fuel blends uniformly with the air for appropriate burning, bring about boosted gas effectiveness and lowered discharges

There are mostly 2 i was reading this kinds of fuel shot systems utilized in small car engines: port fuel injection (PFI) and straight fuel shot (DFI) PFI systems infuse gas right into the consumption port before the intake valve, while DFI systems inject fuel directly into the combustion chamber. Both systems have their benefits, with DFI providing better gas atomization and PFI providing a more cost-efficient option.

Comprehending Engine Cooling Mechanisms

Reliable procedure of a compact car's engine depends greatly on the efficiency of its cooling mechanisms. The cooling system in a small lorry normally Our site is composed of numerous parts working together to control the engine temperature. Understanding these engine air conditioning systems is essential for preserving the performance and durability of a small automobile's engine system.

Exhaust System Components Explained

The optimal functioning of a small automobile's engine cooling systems depends on a corresponding system known as the exhaust system, which comprises different vital components for guaranteeing effective exhausts and engine efficiency. The exhaust manifold accumulates exhaust gases from the engine's cyndrical tubes and courses them to the catalytic converter.

One vital part of the exhaust system is the oxygen sensing unit, which keeps an eye on the oxygen levels in the exhaust gases to aid manage gas consumption and make certain optimal engine efficiency. opel corsa engine. Additionally, the resonator might exist in some exhaust systems to lower sound degrees. Generally, the exhaust system plays an important function in preserving engine performance, reducing damaging discharges, and making sure a quieter driving experience for small vehicle proprietors

Verdict

To conclude, the compact lorry's engine system is a complex mix of components that function with each other to help with the burning procedure, transform gas right into power, and expel waste gases. Understanding the internal functions of the engine system, including the piston and cylinder communication, gas shot system, engine air conditioning devices, and exhaust system parts, is important for keeping ideal efficiency and performance of the car.

The combustion process in a small lorry's engine system is a vital mechanism that successfully transforms gas right into power to power the car.Fuel injection systems in small lorry engines play a critical role in exactly providing fuel to the combustion chamber great site for effective and regulated ignition.There are largely 2 kinds of gas shot systems made use of in portable lorry engines: port gas shot (PFI) and straight fuel injection (DFI) Comprehending these engine cooling mechanisms is important for preserving the performance and longevity of a compact vehicle's engine system.

The optimum performance of a small car's engine air conditioning devices depends on a complementary system recognized as the exhaust system, which makes up different necessary parts for making sure effective discharges and engine performance.